PUMP SOLUTIONS

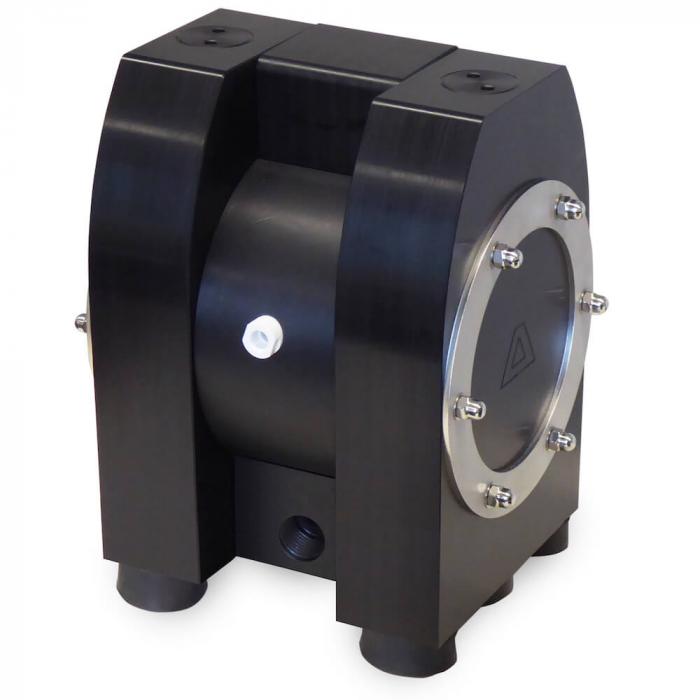

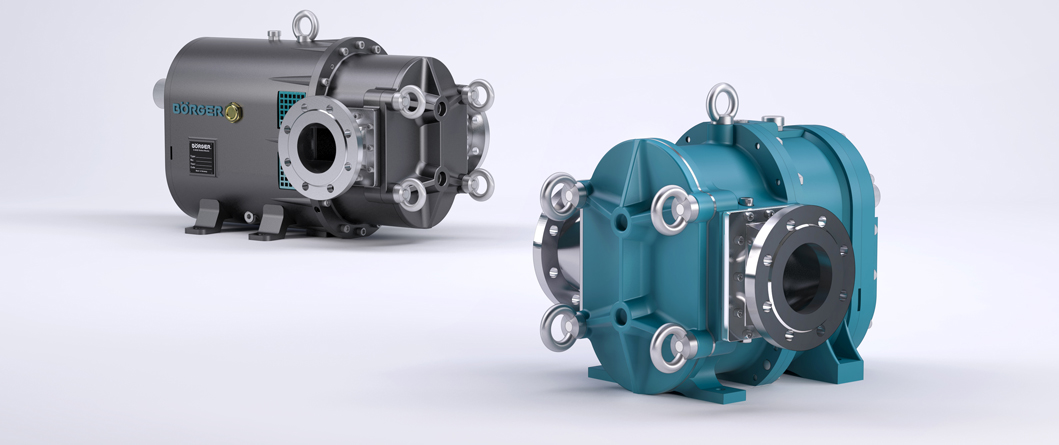

Rotary Lobe Pumps

Boerger GmbH is a leading international manufacturer of high-quality rotary lobe pumps. Founded in Germany in 1975, the company has built a strong reputation for engineering excellence, innovation, and reliability. Boerger’s products are known for their durability, ease of maintenance, and ability to handle a wide range of media, including viscous, abrasive, and chemically aggressive substances.

All products are manufactured at the German headquarters in Borken-Weseke. The family enterprise has currently more than 330 members of staff globally.

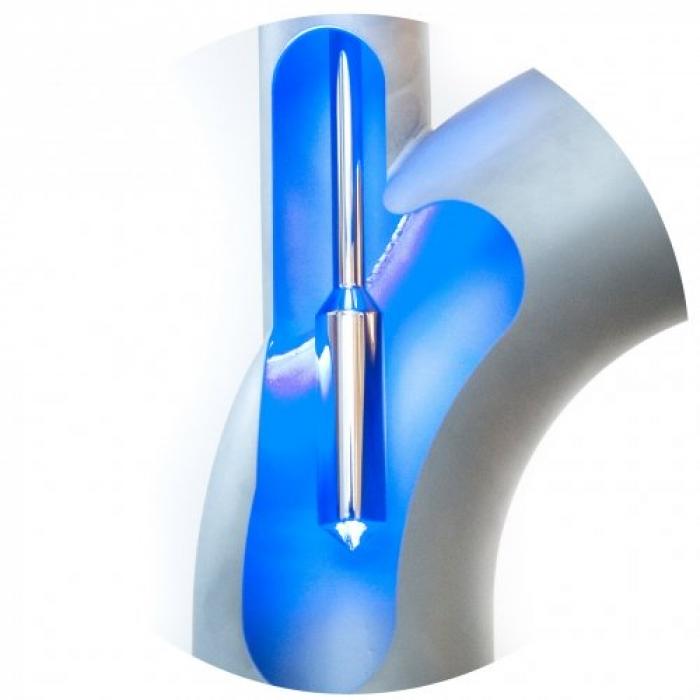

The design of Boerger’s pump features synchronized rotor pairs rotating within a non-segmented casing. This design creates a vacuum that draws fluid into the chamber before displacing it, producing gentle, reversible, and nearly pulsation-free flow. The intermediate chamber contains oil, lubricating the gears and seals and enhancing durability.

Boerger pump characteristics:

- Available in three configurable series—BLUEline Nova, BLUEline Legend, and ONIXline

- 25 sizes

- Flow rates from 1 to 1,440 m³/h (4.4 to 6,400 US gpm)

- Pressures up to 16 bar (230 psi)

- Multiple materials available for the pump casing: cast iron, cast or stainless steel, duplex, or Hastelloy®, to suit diverse applications

- Various rotor geometries and coatings available to optimize flow and lifespan

- Designed for abrasive, solids-laden fluids.

- Compliance-ready: ATEX-, API-, NACE-rated, and customizable for hazardous or sanitary environments

Boerger tests every pump in its in-house facility to ensure real-world reliability.

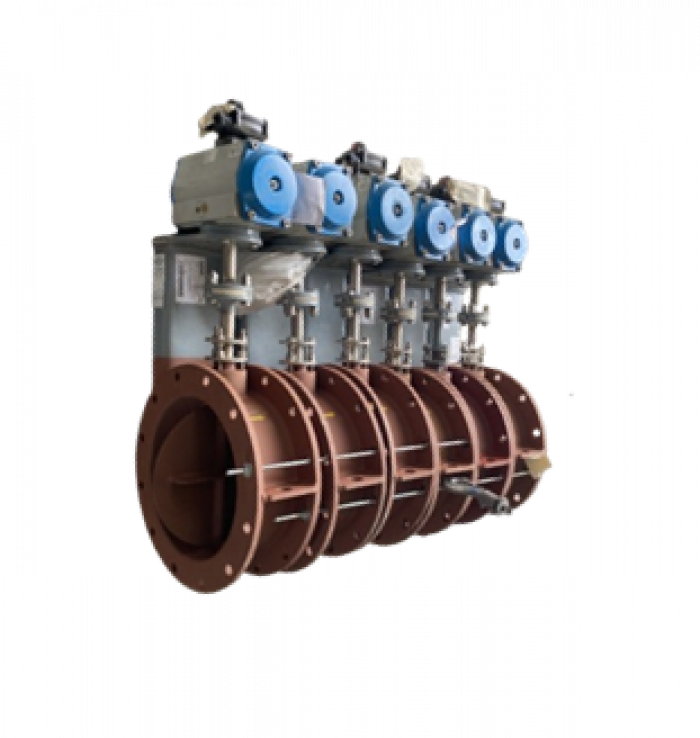

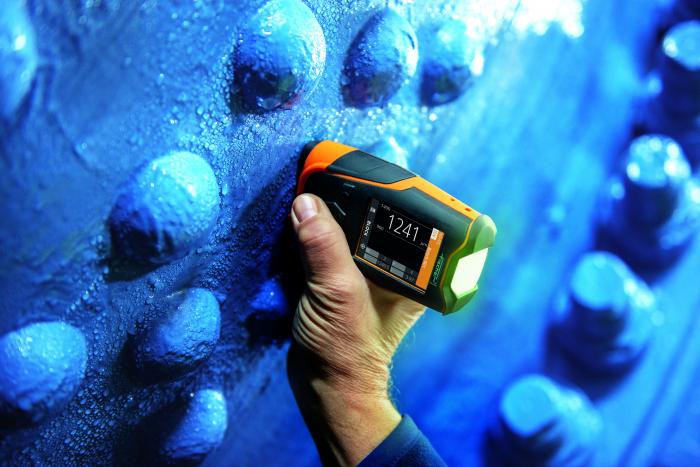

Boerger Pumps Marine Applications

Boerger rotary lobe pumps are trusted in marine environments for their robust design, compact footprint, and high resistance to corrosive and abrasive media. Whether used for bilge water, ballast systems, sludge transfer, or tank cleaning operations, these self-priming, reversible pumps provide reliable, low-maintenance performance in harsh offshore conditions. Their MIP® (Maintenance in Place) feature ensures quick servicing on board, minimizing downtime and maximizing vessel efficiency. With compatibility for ATEX zones and available in marine-grade materials, Boerger pumps meet the demanding standards of shipbuilding and marine operations worldwide.

Boerger Pumps Oil & Gas Applications

In the oil and gas sector, Boerger pumps deliver precise, high-pressure fluid handling for upstream, midstream, and downstream operations. Capable of transferring everything from drilling muds and produced water to sludges, emulsions, and separator fluids, these rotary lobe pumps are engineered for durability in extreme environments. Their modular construction allows customization for chemical compatibility, solids handling, and pressure requirements, while their consistent flow and low shear make them ideal for sensitive or abrasive media. With proven reliability in onshore and offshore installations, Boerger pumps are a trusted solution for efficient, safe, and continuous operation in the energy industry.

Designed for robust performance in tough operational environments, these pumps are trusted in over 100,000 installations worldwide.

Whether stationary, mobile, submerged, or ATEX-rated, Boerger pumps adapt to virtually any application.