Measurement and analysis instruments from FISCHER are used around the world in diverse sectors – wherever precision, reliability and easy operation are required. Helmut Fischer provides the best quality possible products & solutions, starting with the very first contact and continuing through to the creation of individual service concepts. For over 70 years, Helmut Fischer has driven innovation in non-destructive testing, providing high-precision instruments for coating thickness measurement, material analysis, hardness testing, micro-indentation, and XRF analysis. Trusted globally, Fischer’s tools support quality control across industries such as marine, automotive, aerospace, electronics, petrochemical, and precious metals.

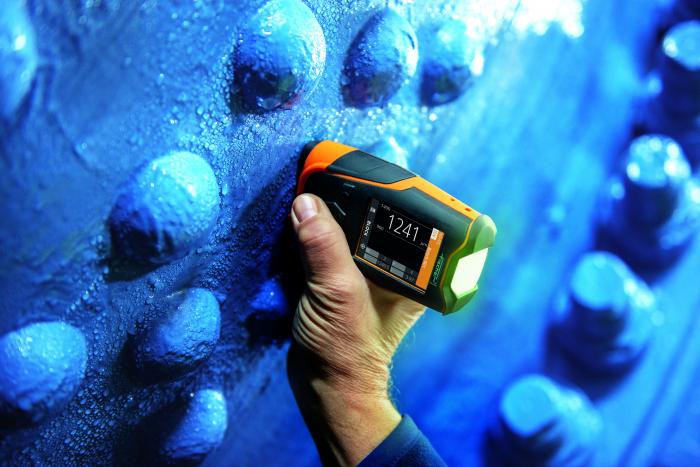

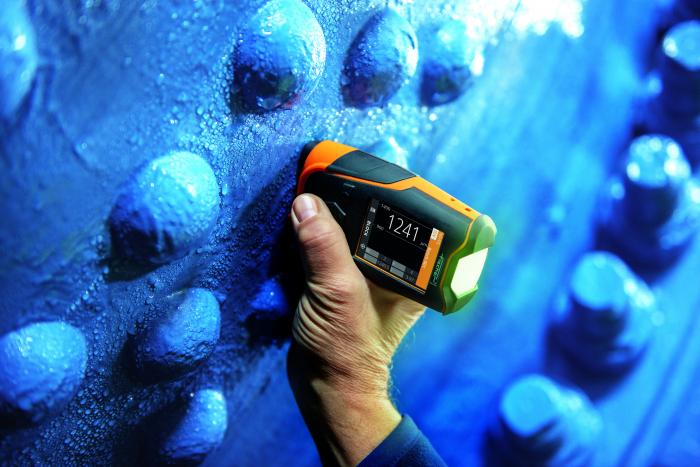

Coating Thickness Measurement

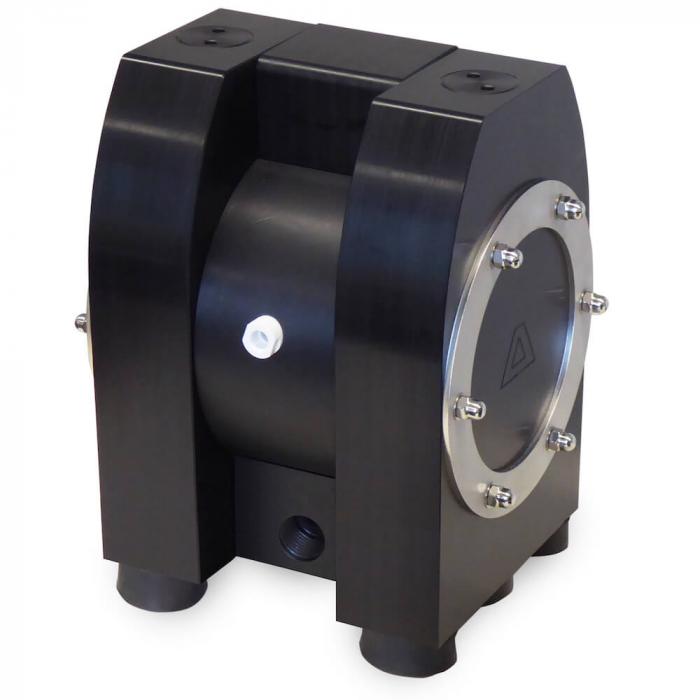

This method delivers nanometer‑level precision for assessing single and multilayer coatings—be they painted, galvanized, magnetic, or conductive—using nondestructive or tactile techniques. Fischer offers a full suite of instruments, from tactile probes and XRF analyzers to terahertz and automated systems, ensuring consistent quality control from production to the end customer, while reducing material use and adhering to industry standards.

Material Analysis

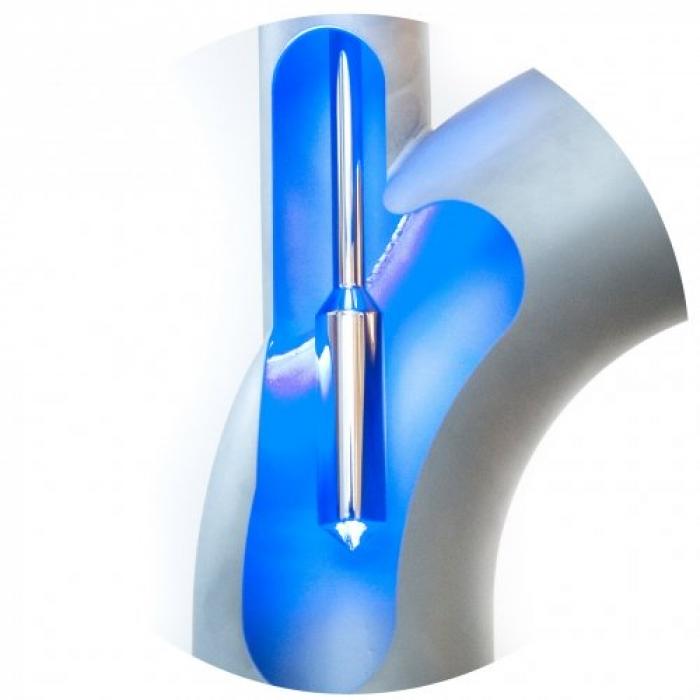

Via energy-dispersive X-ray fluorescence (XRF), Fischer enables precise, non‑contact elemental analysis from magnesium up to uranium. This method is critical for validating material composition, identifying hazardous elements, and ensuring compliance. Solutions range from handheld XRF units to benchtop analyzers—ideal for quality assurance in industrial and laboratory settings.

Micro‑Hardness Measurement

By means of instrumented indentation (following EN ISO 14577/ASTM E2546 standards), these systems quantify material resistance to deformation and penetration at micro- and nanoscales. They rapidly assess mechanical properties like hardness, elasticity, and creep depth, which is especially valuable for evaluating thin coatings and advanced materials in both labs and high-throughput production environments.

Material Testing

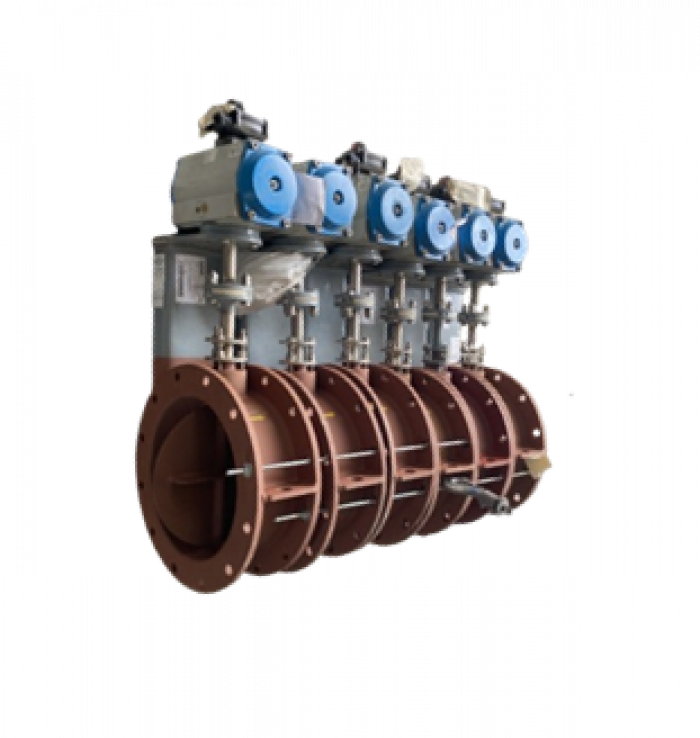

Covering a broad range of non‑destructive testing techniques—including ferrite measurement, conductivity, and hardness—Fischer’s technology aims to detect defects, assess strength, and characterize surface or subsurface properties. These fast, reliable methods are vital for ensuring durability and safety in applications like welding, corrosion protection, and functional coatings.

Relevant Fischer Machines

MP0®, DUALSCOPE® FMP100, DUALSCOPE® FMP150, PHASCOPE® PMP10, COULOSCOPE® CMS2, COULOSCOPE® CMS2 STEP, BETASCOPE®, FISCHERSCOPE® X‑RAY XULM®, XUL®, XDV‑µ, XDL®, XDAL®, XAN® 500, X‑RAY 4000, X‑RAY 5000, TERASCOPE®, XAN® LIQUID ANALYZER, FISCHERSCOPE® HM2000 S, FISCHERSCOPE® HM2000, PICODENTOR® HM500, FISCHERSCOPE® MMS® PC2.

GOLDSCOPE® SD – Precious Metal XRF Instruments

The GOLDSCOPE® SD series is designed for efficient, non-destructive XRF analysis of gold, silver, platinum, and jewelry alloys:

- Compact benchtop units (SD 510/515/520) and advanced SD 600 model with silicon drift detector and video camera for thick samples.

- Pre-programmed WinFTM® software for plugin use in pawnshops, refineries, and jewelry labs.

- Measures alloy composition, plating thickness (e.g., gold on silver, rhodium), and phosphate layers—compliant with EN 61010, ASTM B568, and other standards.

- Next-gen SD 600 includes DPP+ pulse processing for higher accuracy and faster analysis.

Why Choose Helmut Fischer?

- Comprehensive technology suite: Magnetic induction, XRF, eddy-current, beta, terahertz, coulometry—covering all coating and material testing methods.

- Accurate, traceable results: Factory-calibrated, DAkkS-certified, compliant with ISO, ASTM, IMO, SSPC, etc.

- Flexible formats: Portable handhelds, benchtops, inline automation, and lab-style testers.

- Global service & support: German engineering, worldwide distribution, calibration, training, and seminars.

Industries Served

- Marine & Offshore: Hull & tank coating inspection, corrosion control – link to HLF MARINE “SEE MORE”

- Automotive & Aerospace: Paint, plating, thin-film verification

- Electronics & Semiconductors: PCB, wafer, and micro-layer analysis

- Plant & Energy: Pipe, vessel, and structural coating checks

- Jewelry & Precious Metals: Alloy testing and plating evaluation with GOLDSCOPE®

- Pharma, Food, Chemicals: Hygiene and formulation control

- Research Labs: Nano-indentation, material analysis

Visit our Helmut Fischer Webshop here:

Helmut Fischer Webshop