Brochures & Downloads

Activated carbon filters are proven and cost-efficient technology for treating tank emissions, oily water vapors, siloxanes, VOCs, and odorous gases. Thanks to the adsorption properties of activated carbon, contaminants are captured at the molecular level, ensuring odor control, environmental protection, and workplace safety. These systems are widely applied in wastewater treatment, sludge facilities, biogas upgrading, industrial terminals, and refinery tanks.

Tailor-Made Solutions by Pantechnic

At Pantechnic Ltd., we design and manufacture customized active carbon filter systems, engineered with accurate calculations according to each project’s design criteria. Our solutions can be supplied as compact filters or as large multi-bed installations, often integrated with odour reactor systems for complete emission treatment.

Features & Advantages

- Variety of carbon types absorb emissions from oil and oily water tanks.

- Vertical or horizontal alignment, available in single or multi-layer designs.

- Stainless steel SS316 construction, robust against corrosive environments.

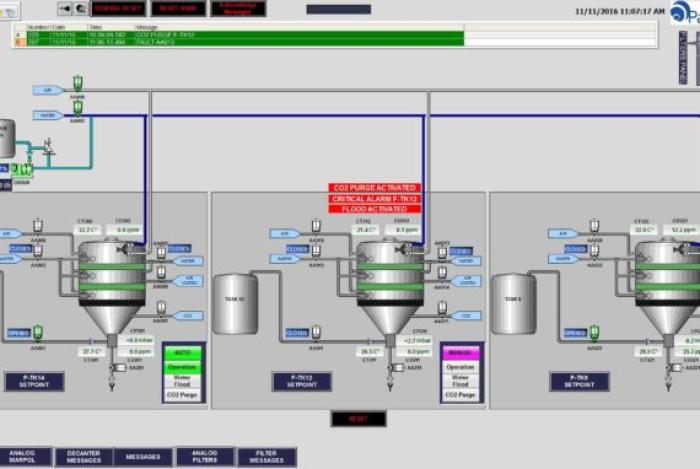

- Advanced alarm systems, cooling and firefighting automations for maximum safety.

- ATEX-certified equipment and CE-marked systems, ensuring compliance and reliability.

- Detailed operating instructions, safe filling & emptying devices, and on-site staff training.

- Documentation, drawings, QA/QC certificates provided with each system.

- After-sales support, including consumables (carbon refills, odor control chemicals) and spare parts.

- Manufactured in Greece, with full commissioning on site by our engineers.

- Calculated pressure drops for filter and piping, ensuring predictable performance.

Proven Experience

Pantechnic has delivered active carbon filters across multiple industries:

- Biogas treatment filters for siloxane removal (up to 90 m³/h).

- Sludge plant exhaust air systems, combining dual-layer SS316 filters with ATEX fans and downstream odor reactors.

- Tank vent filtration systems for industrial terminals and refineries, ensuring compliance with emission regulations.

Why Pantechnic

Our scope covers design, fabrication, automation, installation supervision, commissioning, and training. Every system is delivered with complete QA/QC documentation, pressure and welding reports, and international standard compliance.

With a proven track record in odor management and air purification, Pantechnic offers turnkey activated carbon filter systems that combine safety, efficiency, and reliability – ready to operate from day one.