Brochures & Downloads

Cooling the MGO – Raising the Viscosity with Kelvion PHEs

With the revised MARPOL Annex VI regulation limiting sulfur content to 0.1% in SECA areas, Marine Gas Oil (MGO) has become the most widely used fuel. The challenge, however, lies in its low viscosity, often below the recommended limits for safe engine operation. To address this, a reliable MGO cooling system is essential.

Pantechnic & Kelvion Partnership

At Pantechnic Ltd., we design and manufacture customized MGO Coolers, incorporating the advanced plate heat exchanger (PHE) technology of Kelvion — the heart of the cooler. With the support of Kelvion’s MyKelvion software, we select the correct PHE configuration to guarantee efficient cooling and compliance with engine makers’ strict requirements.

Delivery Options

We offer complete flexibility to meet client preferences:

- Standalone Units – supplied directly from Kelvion, with plate options in titanium (for seawater) or AISI 316 stainless steel (for freshwater).

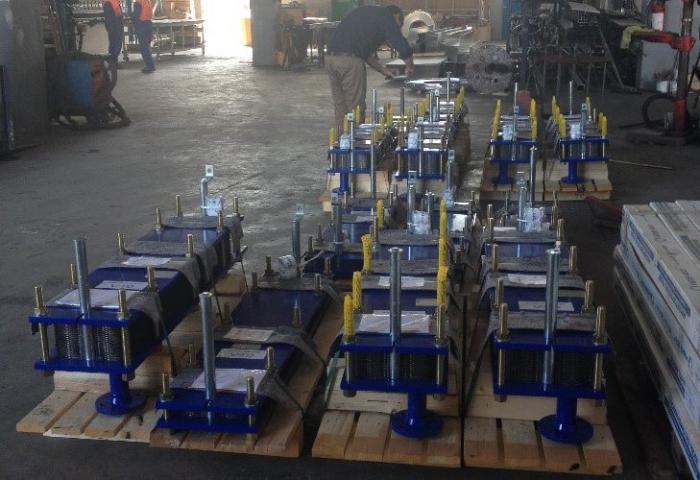

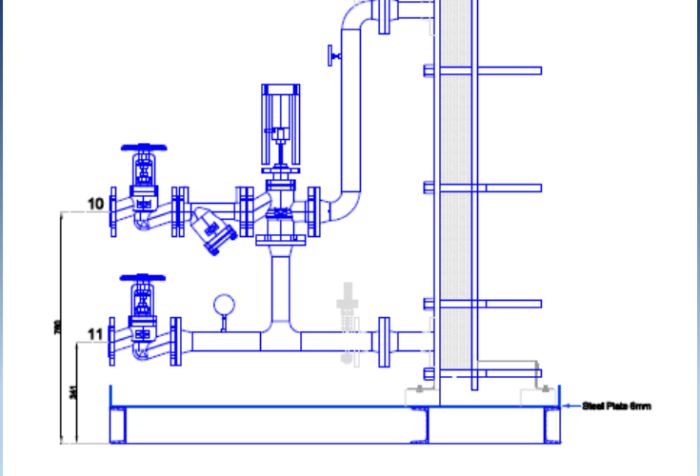

- Skid-Mounted Units – manufactured in Greece by Pantechnic, integrating all piping, instrumentation, and automation required for safe and smooth operation.

Skid Features

Our skid-mounted MGO Coolers are engineered for durability and ease of installation:

- European equipment and instrumentation, including three-way diverting valve, strainer, shut off and butterfly valves, and thermometers.

- UNP 120 steel beam foundations and 6 mm thick drip tray for robustness.

- SCH 40 piping (DN25–DN50) sized according to MGO flow rate.

- Corrosion protection for C4 industrial environments, final coating RAL 5002.

- Full QA/QC documentation, including third-party inspections, pressure and welding tests, coating reports, and quality certifications.

Operation & Control

- Manual mode: simple regulation via a three-way valve and local temperature indication, ideal for stable conditions.

- Automatic mode: with PID control, sensors, and actuated valves, ensuring a safe cooling rate of <2 °C/min as required by engine manufacturers.

Proven Experience

Pantechnic has delivered MGO cooling systems for leading shipping companies, both as retrofits and for newbuild projects. Combined with our track record in odour reactor systems for oil terminals and sludge treatment plants, our portfolio demonstrates a unique capability: to engineer, fabricate, and deliver turnkey fluid handling and conditioning systems that meet international standards and operational demands.