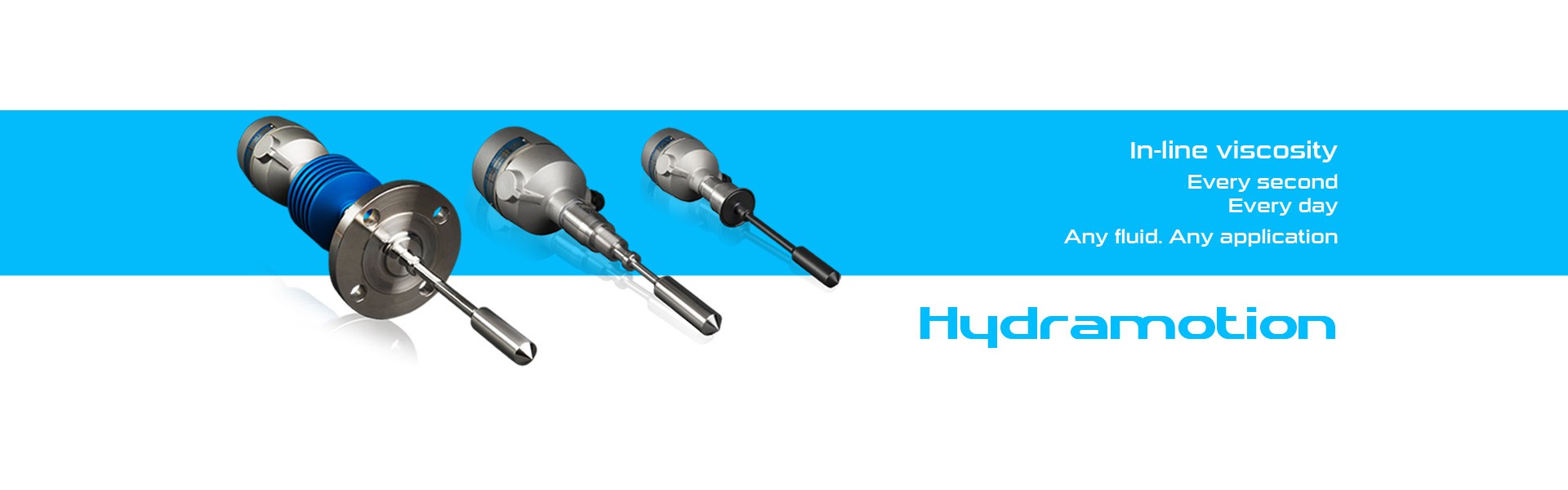

Hydramotion specialises in in-line fuel oil viscometers and conditioning modules. With no need for bypass loops or complex modifications, Hydramotion’s solutions ensure faster installation and increased operational efficiency.

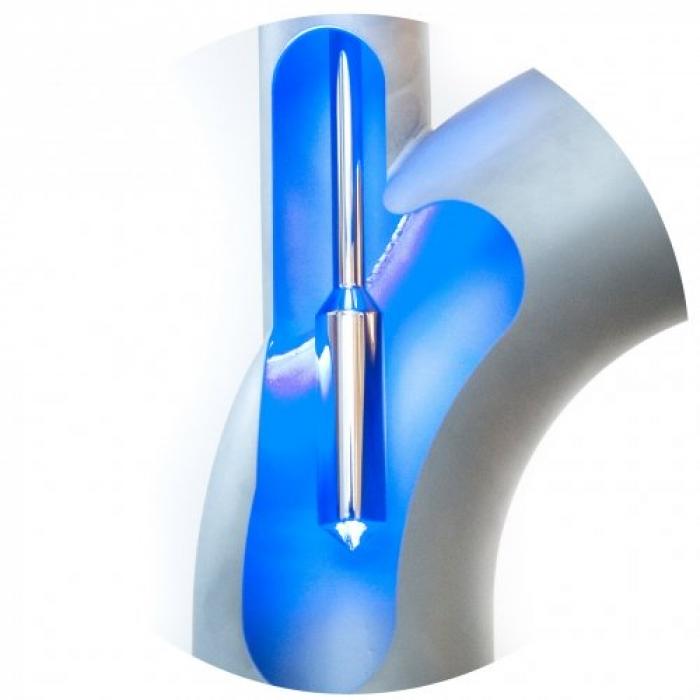

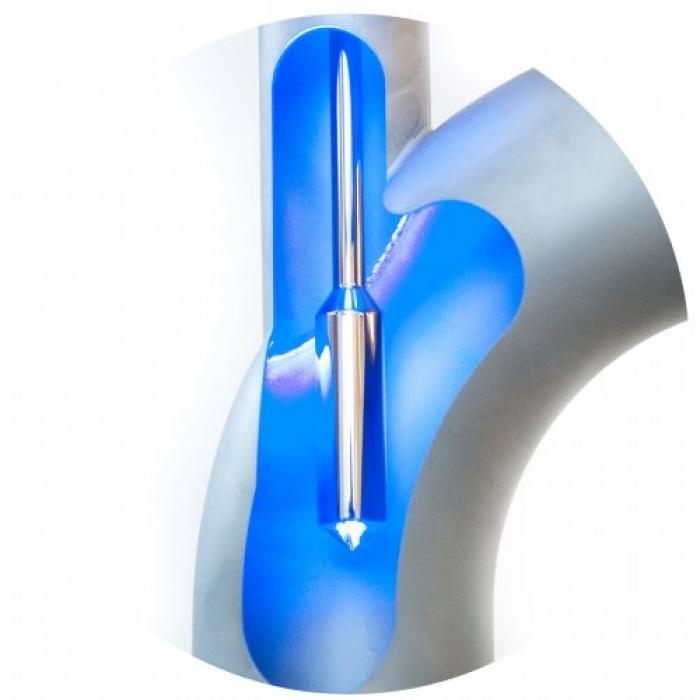

They pioneered a modern resonator design to overcome the limitations of traditional vibrating probes. Their inline viscometers use solid-state resonance sensors that deliver high accuracy, robustness, and virtually zero maintenance. These sensors reach molecular precision, even in turbulent or high-flow conditions—providing uninterrupted, real-time data essential for process control.

Hydramotion’s devices are designed for straightforward integration. Whether upgrading an existing fuel line or adding inline monitoring, these viscometers offer a fast and easy retrofit.

They understand the power of measuring viscosity in the process. It’s about reaching deep into the fluid and giving the operator, plant manager, or researcher a precise understanding of what is happening to their product in microscopic detail. And doing this instantly, in all conditions including incredibly fast and turbulent flow. Molecular precision in the eye of a storm.

Hydramotion’s advanced inline viscometers are trusted across a wide range of industries for real-time viscosity measurement and process optimization.

Key Application Areas:

- Marine Fuel Viscosity Monitoring

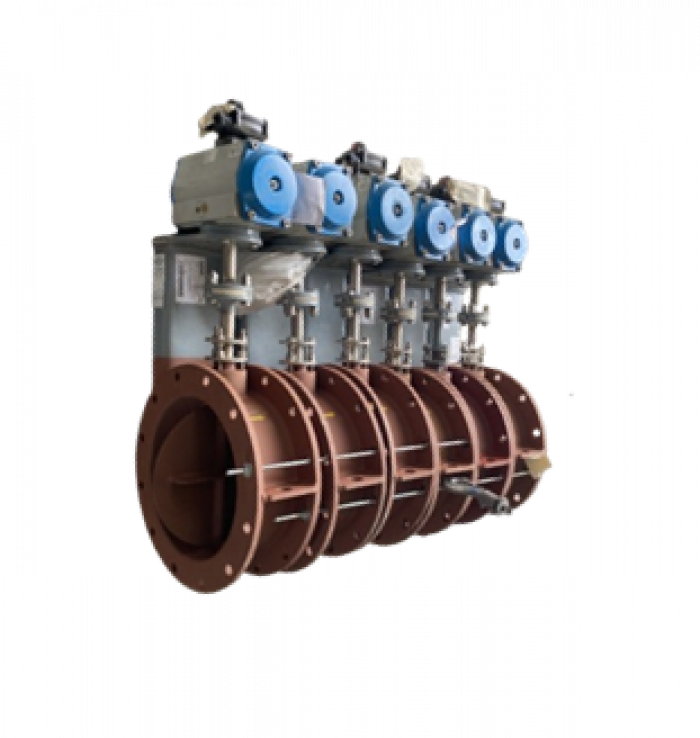

Hydramotion viscometers play a vital role in marine fuel oil systems, providing accurate viscosity control during bunkering and engine combustion to ensure compliance with emissions regulations and optimize fuel efficiency. - Oil & Gas and Stationary Power Applications

In refineries, gas processing, and power plants, Hydramotion devices help regulate fuel and lube oil viscosity in stationary engines, enhancing performance, lowering operational costs, and reducing environmental impact. - Petrochemical & Industrial Processing

Inline viscometers are essential for chemical manufacturing, refining, and polymer production, where consistent viscosity is key to maintaining product quality, formulation accuracy, and batch repeatability. - Food, Beverage & Pharmaceutical Manufacturing

Hydramotion sensors ensure viscosity consistency in food products, sauces, dairy, cosmetics, and pharmaceuticals, supporting hygienic processing, clean-in-place (CIP) compliance, and quality assurance. - Inks, Coatings & Paints

In coating and printing lines, real-time viscosity measurement helps control coating thickness, print quality, and drying rates, improving productivity and reducing material waste.

Why Hydramotion

- Lab-grade precision delivered in-line, every second

- Durable and maintenance-free design—solid-state, no moving parts or recalibration

- Plug-and-play retrofit simplifies upgrades with minimal plant disruption. Easy replacement of existing equipment

- Resilient performance—immune to bubbles, vibration, flow changes, and temperature

- Global certifications — including IP67, ATEX/IECEx options, and Lloyd’s approval for marine use

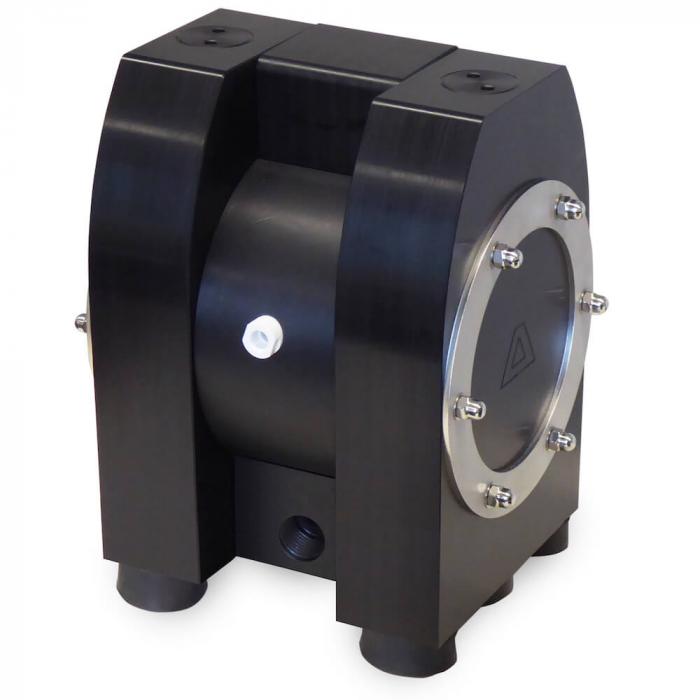

ViscoJet VJ1 Fuel Oil Module

A dedicated inline fuel oil viscometer delivering lab-grade readings every second, ±1 % accuracy, and handling up to 1,000 cP, 150 °C, and 50 bar. It bolts directly into any fuel line without special fittings and requires no maintenance.

Other Products Supplied by Pantechnic

Pantechnic proudly supplies Hydramotion’s innovative products, including:

- XL Series Viscometers

◦ XL7 Standard

◦ XL7 High Temperature

◦ XL7 Long Reach

Lab Series Viscometers

◦ ReactaVisc

◦ GoVisc

Portable Viscometers

◦ Viscolite

Specialized Viscometers

◦ Viscojet – VJ1

◦ Viscolite – VL7

Thruflow Series

◦ Thruvisc Flow Through Small Bore Solution