The proposition for 3D scanning is not simply about improving the efficiency of existing surveying methods. It provides shipowners, operators, and plant managers with a powerful toolkit to achieve measurement goals that were previously unattainable, while establishing a robust foundation for improved asset information management.

Key Benefits of 3D Scanning

- Minimizes onsite presence – often a single visit is enough to capture all required data.

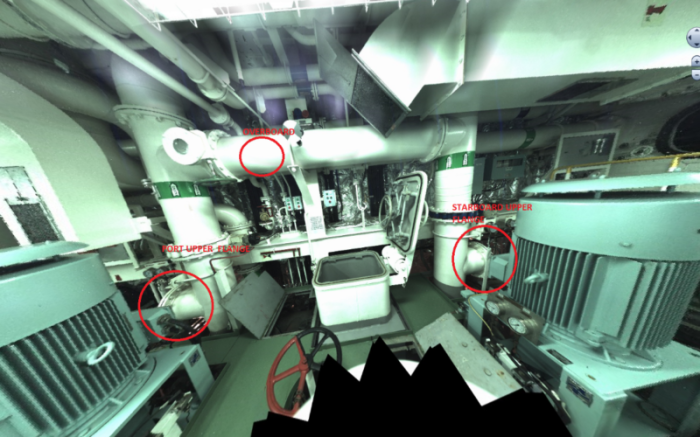

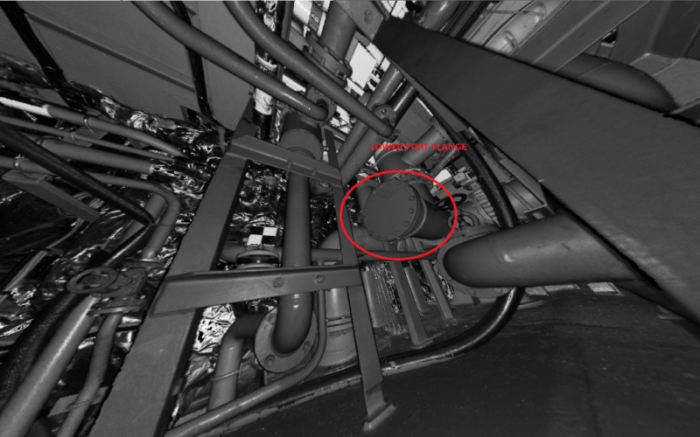

- Captures actual conditions in high resolution, enabling detailed inspection and documentation.

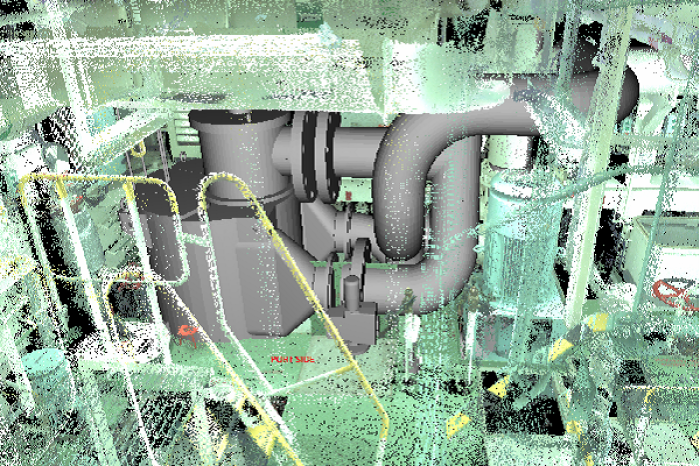

- Simplifies retrofit projects, making the installation of new equipment possible in complex areas (dense piping, restricted spaces, hard-to-reach locations).

- Provides comprehensive digital deliverables – including a high-resolution 3D point cloud file, accurate measurements, and a browsable photo-based HTML file for use directly on a PC.

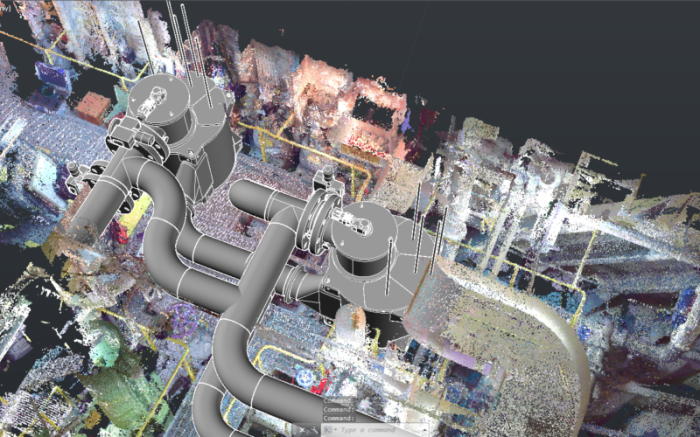

- Enables advanced 3D modeling for design and engineering.

- Supports reverse engineering with highly accurate digital replicas of existing structures.

Applications

3D scanning is a valuable tool across a wide range of marine and land-based projects. Examples include:

- Ballast Water Treatment Systems: Enabling precise design of new units into existing ballast lines, planning pipe routing, and managing modifications with minimal onboard disruption.

- Scrubber Retrofits: Supporting the integration of exhaust gas cleaning systems, particularly in congested engine room spaces, with accurate models for routing large scrubber piping and avoiding structural conflicts.

- Land-Based Industrial Projects: Delivering digital twins of facilities such as process plants, pumping stations, or storage terminals, which allow Pantechnic engineers design expansions, upgrades, or maintenance interventions with confidence.

By capturing a digital representation of the actual environment, Pantechnic engineers can perform most of the design work onshore or offsite, reducing installation risks and avoiding costly rework.

Pantechnic’s Flexibility & Mobilization

At Pantechnic, we combine flexibility with technical expertise. Our compact and portable equipment allows us to mobilize quickly anywhere our clients require. Once onsite, our experienced engineers perform an inspection and carry out the 3D scanning operation, which typically lasts only a few hours depending on complexity.

Because of its compact form factor, our scanning equipment can be carried by a single person, easily transported on barges, and deployed even in confined or obstructed spaces. Despite its portability, it delivers high-precision results, capturing every geometry and feature of the surveyed area for accurate post-processing and modeling.

Scanning Equipment

We use Terrestrial Laser Scanner technology in combination with advanced geodetic techniques, offering the most effective methodology for capturing details of marine and industrial environments.

Our primary instrument is the Leica BLK360 ultra-portable imaging laser scanner, capable of capturing millions of points per scan with a precision of 3–4 mm. The scanner records dense point clouds together with full-color panoramic images, producing intuitive and data-rich outputs for engineering teams.

With the resulting point cloud data, engineers can work in specialized CAD environments to design, model, and plan retrofits or expansions with unmatched accuracy.